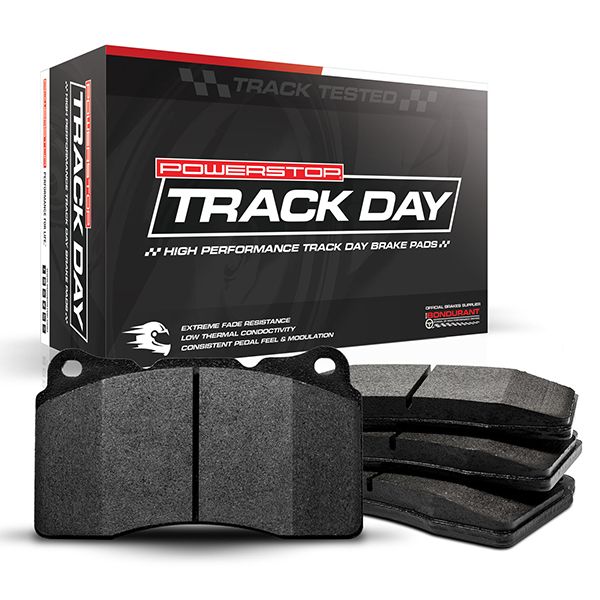

Track Day Brake Pads

Will not fit your vehicle

Will not fit your vehicle

- Recommended For

Beginning track day enthusiasts - Carbon-Fiber/Metallic formulation

Extreme fade resistance at high speeds - Confidence & Control

Consistent pedal feel at every corner - Proven Performance

Official Brake Supplier of Radford Racing School (formerly Bondurant)

Track Day

PowerStop is on a mission to deliver an easy and affordable way for any driver to upgrade their brakes - no matter where or how they use their vehicle. If you drive your street-driven vehicle on a road race circuit for a "Track Day" or HPDE, you certainly know the importance of quality brake pads. PowerStop Track Day Brake Pads are perfect for the entry level track-day enthusiast. The PowerStop research and development team spent countless hours matching the right pad compound to each individual vehicle platform so you don't have to spend countless track days figuring it out yourself. These platform-specific brake compounds have an excellent coefficient of friction and resist fade during the rigors of just about any track day.

- Weekend Track Days

- H.P.D.E.

Track Day Brake Pads Features & Benefits

Track Day - All Hardware Included

WHAT YOU

NEED

TO KNOW

INSTALLATION OPTIONS

Install It Yourself

In the world of vehicle maintenance, replacing your brakes is an easy job to tackle on your own. Our step-by-step installation guides will help you get the job done.

How To Guides Questions? Contact Technical Support [email protected]Take it to a Pro

Not confident in your abilities as a mechanic? No problem! We have a network of installers that are ready to help you out. Bring in your car and your brake kit, and they’ll do the rest.

Find an InstallerWARRANTY & RETURNS

30 Day Warranty

PowerStop LLC warrants this product to be free from defects in materials or workmanship for 30 days from the purchase date. The product, when properly installed in the type of vehicle prescribed, and in which a material or workmanship defect is found, will be exchanged free of charge if returned to the seller who is authorized to service this warranty. PowerStop LLC is not responsible for its products when they are subjected to misuse, abuse, improper application, improper installation, or accident. This 30 Day warranty excludes failure of components due to disc thickness variation (DTV*), usually indicated by brake pulsation. Normal wear is not covered by this warranty.

The PowerStop Difference